The Best Mower Blades For Your Lawn Mower

8/12/2019 5:00:00 AM

How to choose the right mower blade

Mower blades to a new lawn mower are like tires to a new motorcycle. Every new bike comes with tires and every new lawn mower comes with blades, and a new owner of either may consider changing the set equipped with their new product. However, whereas the typical new motorcycle owner is expecting cheap tires with a low wear rating, the case isn’t the same with lawn mower blades. Stock lawn mower blades have no less or no greater quality than any other aftermarket or OEM blade, and actually, it’s wisest for a homeowner to use the factory blades that came with their new mower.

Mower Deck Aerodynamics

Every component on an Ariens lawn mower or snow blower is engineered with a specific purpose and designed exactly for that application. After sitting down with AriensCo engineer Paul Ferrier, we learned that mower blades are no different.

Mower blades are custom components; they are not one size fits all. Mower blade design is specific to the mower it’s used with. From the stamped deck on an Ariens ZOOM 34 zero turn to a 10-gauge, 60 inch welded deck on an Ariens APEX lawn mower, there’s a specially engineered blade for that particular mower deck. Mower decks aren’t designed to simply mount blades and shield discharge, they’re designed to lift grass, cut it and discharge it as efficiently and as effectively as physically possible.

The Best Lawn Mower Blades

Every Ariens mower deck rolling off the assembly line today is engineered, tested and validated for cut quality performance. To the unknowing eye, a mower deck is just a steel shell with blades and baffles, but it’s actually a very delicate system of physics and aerodynamics. Mower decks are uniquely designed for their depth, width, power supply and expected application, and its blades are designed especially for the deck.

“Mower blade geometry and the cutting chambers of a mower deck work in tandem,” said Ferrier. “Their designs rely on each other. For that reason, the best blade anyone can use is an OEM (original equipment manufacturer) blade, because that blade was specifically designed to work with your mower and give your cutting deck its best performance.”

Different Types of Mower Blades

While an OEM blade is the best choice for your lawn, you have a choice in the style of the blade for your desired application. Ariens designs different types of blades to work for both normal and special conditions. For example, manufacturers make blades that lift grass, blades that are more durable in abrasive soils, blades that are advertised to enhance fuel efficiency and blades that mince grass into tiny pieces.

Though Ariens hasn’t designed a blade for all of these applications, we design blades for the conditions that will likely be seen in the yards of our customers. That’s why you’ll often find a large blade selection at your local Ariens dealer, Your dealer can help you find exactly what you need, but if you prefer self service, remember these two points:

- Purchase replacement mower blades that are the exact size as the originals.

- Ensure the blades you buy are the right type for your application.

Read through the different types of blades below to learn which you may want and those which we wouldn’t recommend for a manicured yard.

What are flat / no-lift blades?

This usually won’t be the type of mower blade used for manicured lawns with an even cut and pristine edging along the sidewalk. Flat blades don’t have the air lifts on the ends. They’re exactly as their name suggests – flat, meaning they don’t generate air circulation under the deck.

Though the right-sized flat blade can be installed to a mower deck it was spec’d for, this will likely not be the type of blade installed on an Ariens zero turn mower.

“Flat blades are mostly used for knocking down overgrowth like in ditches, for example,” said Ferrier. “They don’t leave a polished result and they won’t work the best in bagging applications, either.”

What are lift blades?

Lift blades are the style of blades that come with a mower fresh off the Ariens assembly line and are commonly used in a homeowner’s applications because they provide the best cut quality.

Lift blades utilize an “air-lift” or a flared bend at each end of the cutting blade to generate a deck’s aerodynamics and the vacuum that helps pull grass upward to give it a uniform, even cut across the width of the deck. Just remember, the deck will need to be pitched correctly and other conditions will have to be satisfied to take advantage of a deck’s aero package and to achieve the quality of cut boasted by lift blades.

Lift blades are best for bagging. The design of high lift blades, in conjunction with the mower deck engineering, influence the aerodynamics that allows grass to circulate around the mower deck and discharge evenly. This is important while bagging because the clippings need to be discharged at a height which can enter the bagger system most effectively.

What are mulching blades

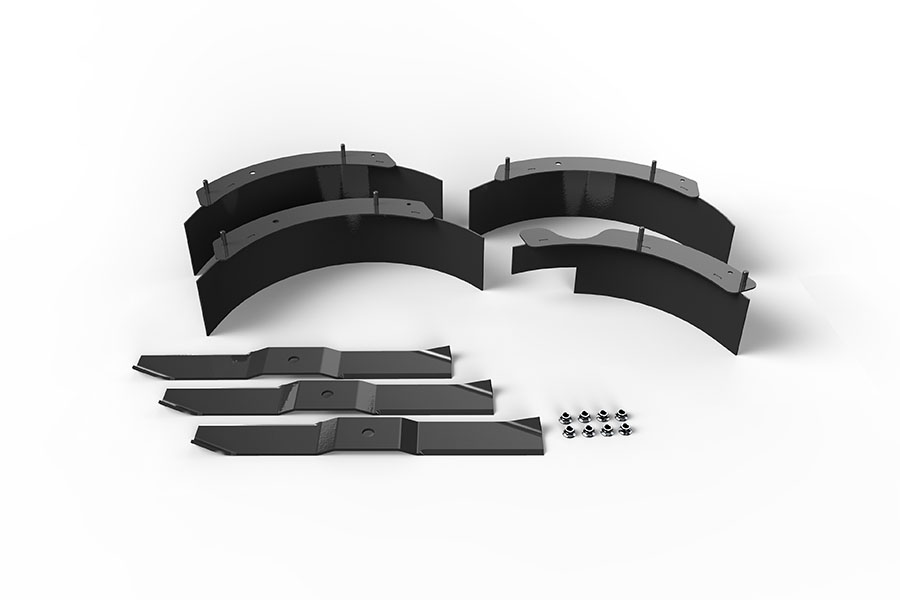

Mulching is an easy, economical and sustainable method for thickening lawn density. Mulch kits use a mower deck baffle system that blocks the discharge opening of a mower deck and specially designed mulching blades to cut and recut grass clippings into smaller, decomposable grass clipping particles. These particles, which are not discharged or bagged, fall to the lawn bed where they decompose and feed a lawn so it grows thick and green.

Mulch blades, which feature air lifts that generate air circulation throughout a mower deck, have special geometry and more cutting edges along the length of the blade to mince grass into those tiny clippings.

Mulch kits have useful application in any lawn and can be installed to any Ariens zero turn mower.Click here to learn all about mulching and its benefits in a blog post we produced earlier this year.

What’s a serrated blade?

Some people swear by them, and others don’t. The average homeowner may not get as much from a serrated blade, but they could make a difference for those who live on a large amount of mowable acreage.

Serrated blades can be lift blades and mulch blades, but their unique feature is in the serrations in the lift area of the blade which is designed to reduce the blade’s surface area. The intention behind a blade with less surface area is that there’s less air resistance and drag on the blades, meaning they'll cut through air more easily. Theoretically, that requires less effort from the mower, which increases its efficiency. However, validating a serrated blade’s effectiveness may require measuring the fuel consumption against a control variable over time in larger mowing areas.

Ariens doesn’t manufacture serrated style blades for a couple reasons. First, they don’t give much back to a homeowner who maintains a small area of turf. Additionally, as serrated blades wear, their serrations have the potential to become brittle, break off and turn into projectiles. In the chance for that scenario, we suggest staying away from serrated blades.

LaserEdge® blades

LaserEdge blades are especially useful for commercial lawn maintenance applications, but homeowners who live in Florida, South Georgia and other areas with sandy soil or otherwise abrasive soil conditions could still have use for LaserEdge blades.

When mowing in abrasive soils, the air circulation under a cutting deck can kick up enough sand and grit to turn the cutting chamber into a sandblaster, causing the mower blade material to wear much faster than in normal conditions. In fact, commercial landscapers in Florida sharpen or replace their blades at least once per week because of their soil composition.

LaserEdge blades feature a strengthened layer of material below their cutting edges. As the top layer of the cutting edge wears away from the abrasion, the longer-lasting, reinforced bottom creates a new cutting edge and extends the blade utility. Even though residential users are cutting nowhere near the maximum hours of a commercial lawn mower, LaserEdge blades can provide the same savings. Extended blade utility means the same quality of cut with less sharpening and less replacements, making LaserEdge blades the mower blade with the best value.

While LaserEdge blades were designed mainly for commercial lawn mowers, their application is still useful for homeowners. However, be aware that since these blades were designed for commercial use, their fit is more limited to a prosumer lawn mower, which is a residential zero turn with commercial features. In the Ariens lineup, that would be the Ariens APEX.

Click here to buy LaserEdge blades.

How to sharpen mower blades

Mower blades are like the knives in a kitchen. After too much use, they become dull, work less effectively and damage your grass. Dull mower blades tear grass blades instead of cutting them cleanly, causing grass to become stressed. That stress can do a lot of damage to your lawn, causing it to look unsightly and worse – requiring you to spend time and money fixing the damage.

Frayed grass blade ends allow moisture to evaporate from a lawn more easily, requiring more irrigation and more money spent keeping it green. But no matter how much water you dump on your grass, fraying causes grass blades to become so stressed and damaged that their ends will turn brown anyway. A little brown spot on just one blade is no big deal, but when your entire lawn is littered with frayed grass blade ends, it leaves a tan hue across your entire lawn. Take a picture of a healthy, green lawn and put it next to one with damaged ends and you’ll notice the difference.

Torn grass is also more susceptible to turf disease because its frayed openings leave more entry points for harmful pathogens, such as a variety of fungi. Though lawn diseases can be treated and cured, it’s just another annoyance that can cost time and money. Help avoid those issues by sharpening your blades.

Mower blade sharpening isn't difficult, but it requires experience and the right tools. Clamps, a metal grinder and the right safety gear is all that’s needed to sharpen a blade, but we don’t recommend attempting it without lessons. If you’re a first timer, take your blades to your local Ariens dealer and have them do it for you.

Balancing mower blades

Experience is recommended for sharpening blades not only for safety reasons, but because blades are sensitive pieces of engineering. Like the wheels on a car, blades need to be balanced. Without blade balance, a mower deck will experience excessive vibration and you’ll be left with an uneven and very unattractive cut quality.

Think of a blade as an object with two weighted ends, each end being the other’s counterweight. As blade material is removed during sharpening, the blade’s weight changes on one side, meaning the other side will need to be filed equally to maintain balance.

How to balance a mower blade

To check blade balance, insert an unthreaded bolt or a screwdriver through the blade’s mounting hole and place the screwdriver horizontally. Place the blade horizontally and observe the blade movement. If one end of the blade moves down and makes the blade vertical, file away more material from that end of the blade and test again. File as needed until the blade remains balanced on the screwdriver.

As always, refer to your operator’s manual to review instructional details when sharpening and or balancing your mower blades.

If your blades are beyond sharpening, find replacements at your local Ariens dealer. Or, if you know the replacement blade numbers for your mower, you can purchase them online at parts.ariens.com.