Snow Blower Maintenance Tips

2/7/2023 3:17:10 PM

Check The Auger

Can’t expect to gather a lot of snow if you don’t have good augers onboard – seems kinda obvious. For a single-stage unit, this means checking out your paddles. The rubber is designed to scrape directly on the ground, scoop the snow into the back of the housing, and up the shoot. Most paddles have wear indicator holes, when the paddle is worn down to the holes – it's time for a new one. A Couple minutes and some basic wrenches, and you're back to chucking powder.

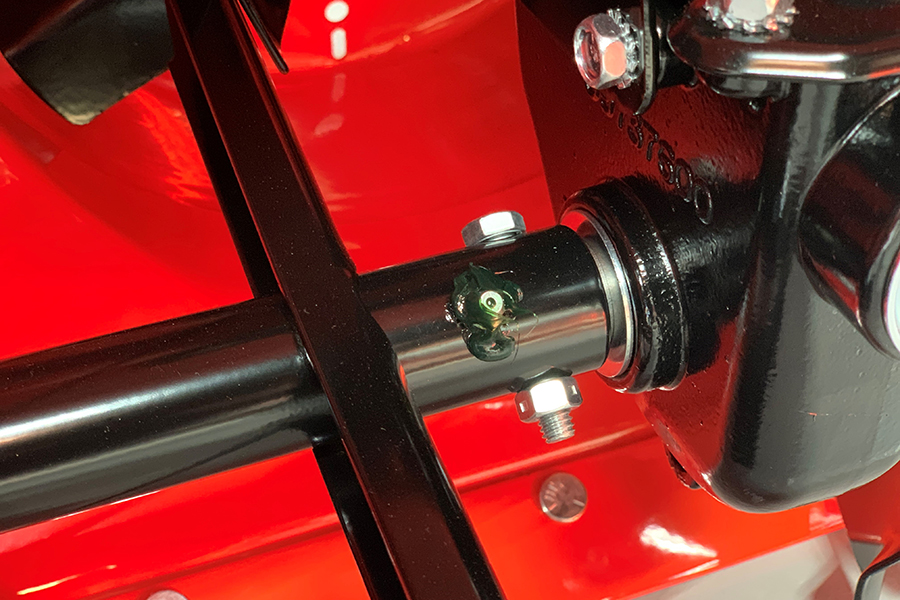

Two-stage augers are a-lot like large metal teeth that chew threw the snow and ice. While they wear too, it happens much slower. That said, because they are metal, there needs to be some grease to keep things moving smoothly. You’ll notice some silver-colored bulbs with small holes, called “zerk” fittings, along the auger shaft. Fit a grease gun over these and fill ‘er up! More on that below, so keep reading.

Snow Blower Lubrication

All-steel construction has been a staple of Ariens products since our first Sno-Thro came off the line in 1960. But with the benefit of durability and reliability of all steel comes the need to keep things lubricated. Metal on metal can cause issues, so it's best to stay in front of that. Your owner’s manual is king on how to do this, but here are some basic tips.

As mentioned, the augers need grease to keep them spinning freely on the shaft. Ideally, you’ve removed the shear pins first for this. Hook up a grease gun and slowly give enough pumps that you start to see grease come out of some of the edges or by the shear pin holes. Then, give the augers a couple spins in both directions to spread the grease out inside. Top off the grease again until you see it start to ooze out, wipe it down, and replace the shear bolts.

The axles are another place to keep greased regularly. At least once per season, remove the wheels from the axles and spread a thin layer of grease or anti-seize compound along the length of the axle shafts. If rust is present on the axles, file it away with sandpaper, wipe clean with a thin layer of oil and then grease.

A few drive gears, a shaft or two and sometimes a chain inside the tractor (the box to which the engine is mounted to) all need to be greased too. Tip the unit onto the front of its housing like you are snow blowing into the floor, remove the bottom cover and lubricate according to your operator's manual.

Clean-up on Skid Row

Scraper bars are attached to the bottom of snow blower housing to help scrape up the last bit left behind. But, as their name indicates, their job is to literally scrape against the ground – making them somewhat sacrificial. Because of this, they need replacement every so often depending on frequency of use and how much it wears. Worn scraper blades won't clear snow as well as they did when they were new. If you start seeing more snow left behind your snow blower, it's a sign you'll need to adjust your scraper blade. If your scraper blade is adjusted as far down as possible and isn't scraping all the snow from the ground, replace it.

Two-stage units have a skid shoe on each side of the housing to maintain the correct height and protect your surface. Skid shoes on Ariens snow blowers can be flipped to the other side, but once both sides wear through, they'll need replacement. Either get direct replacements like what came on your unit, or upgrade – we offer non-abrasive poly skid shoes for delicate surfaces like pavers or even commercial-grade steel ones.

Shore up your Shear Pin Game

Shear pins, hold the auger to the auger shaft but are designed to break (shear pin – get it?) if the auger hits something hard like a rock, a thick branch, or your son’s wagon (yup – that one happened). Trust me, you’d rather replace these than a gearbox. The thing with these is that they always break when you're only half done and can’t find spares. Lucky for you, we have spares available online and at a dealer near you. We even have a nifty holder for spares right on your unit – so be sure you're stocked up before the season. And if yours look worn or old, replace them before the year starts – like when you grease the auger, they are out anyway!

Belts - Strapped up for maximum performance

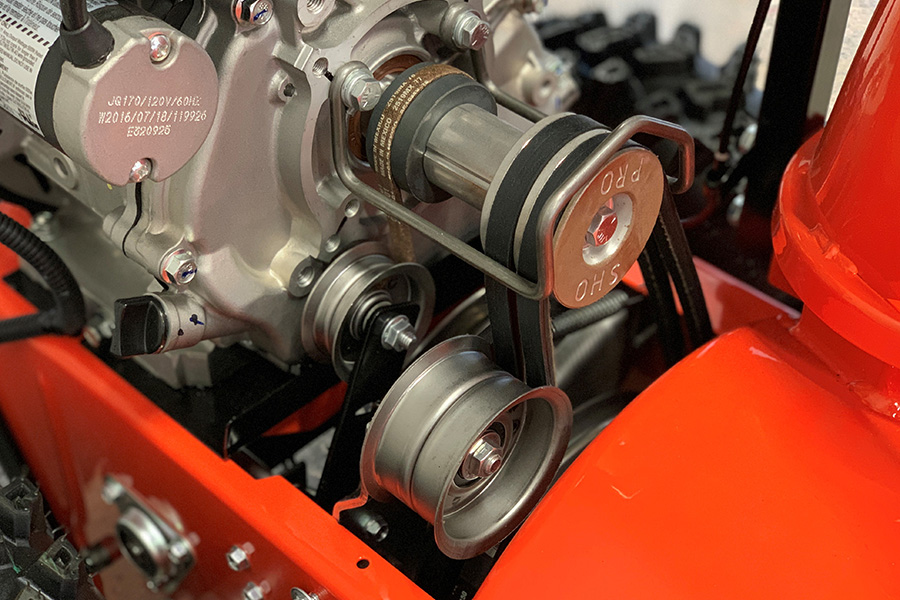

Snow blower belts help transfer power from the engine to the actual sno-throwing bits. If you are into cool belt drive systems, our patented dual-belt-drive system on our higher end two-stage units is actually a really exciting feature – read about it here.

Even with cool features like dual-belt-drive, belts eventually need replacement. Common issues with belts over prolonged use include sidewall damage, glazing, and cracking. Sidewall damage, or edge fraying, is when the belts start to get little hairs along the sides. Glazing, or burnt belts can often look like the face is almost shiny or “glazed” from too many trips around the pullies. Cracking belts are just that, little cracks usually start to appear on the face of the belt as the rubber ages through multiple heat cycles. All of these are signs its time for your belts to retire and let the next generation take over.

Change The Oil

Engines need oil – I’m guessing this statement doesn’t shock you. And if they need oil, then that oil doesn’t last forever, it’s a fact of life. Oil changes on these units are very easy – if you can turn a handle (wrench handle) and pour with limited spilling, you can probably pull this one off. Check your manual for the details but it is generally recommended about once a year. We even have a nice detailed guide on how to do it in another blog here.

Keeping Spark Plugs Sparky

The spark plug is the light that makes the magic happen – it literally is the light that makes the fuel in an internal combustion engine, well, combust. So yeah – kind of a big deal you could say. Understandably, if your entire job is to light on fire multiple times a second, eventually you get old and need replacement. Good news here, if you thought oil changes were easy – spark plug replacement is even easier. Still need to turn a wrench but no need to worry about spilling anything. Check your owner’s manual for the specifics but generally spark plugs need to be changed after a couple seasons or 100 hours of use – whichever is first. Gently pull the wire off the top, unscrew the old one with a spark plug wrench, screw in the new one (gently) and replace the wire on top. When the wire “pops” on, its good!

Snow blower maintenance should not be something that gives you too much anxiety. In fact, it's these simple things are what keep these units running longer than you could ever expect. Plus, rolling up your sleeves for an afternoon each fall to pre-season prep your machine can actually be fun, so enjoy it! However, if getting a little dirt under your nails is not your style – that’s fine too, just give a ring to your local Ariens servicing dealer and let them have all the fun. Or, better yet, a new unit comes out of the box all ready to go, no maintenance needed, and your favorite Ariens selling dealer can help you with that too!

AUTHOR

Nik Krueger, AriensCo Product Manager – Snow

A Wisconsin native, Nik is no stranger to snow. Growing up in an Ariens household, his first experience with a Sno-Thro was being promoted from shovel to ST824 as a kid. As the product manager for all Ariens Snow products since 2021, Nik has enjoyed being part of continuing to grow the Ariens heritage and product line. When his driveway (and the neighbors’) is clear, he enjoys time snow skiing, snowboarding, and tubing with his kids.